| Sign In | Join Free | My bjjsgy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My bjjsgy.com |

|

Brand Name : Shitan

Model Number : ST-200

Place of Origin : Hebei China

MOQ : 1 set

Price : 35000 USD-45000 USD

Payment Terms : T/T,Western Union

Supply Ability : 2000 sets/month

Delivery Time : 15-20 days

Packaging Details : Wooden box

Product Name : 200 type tire type water well drilling rig

Drilling method : Mud pump drilling and air compressor drilling

Drilling diameter : Φ105-Φ350mm

Max Rotary Speed : 30-120 r/min

Rod Diameter : 76-89mm

Drilling depth : 200m

Weight : 5.5T

Diesel engine power : Xidong 65 kW

Dimension : 4400x2150x2200mm

Working Condition : Loose layer and bedrock

The 200 type water well drilling rig is a practical equipment suitable for medium and shallow hole drilling, with a drilling depth of about 200 meters, strong power, and stable drilling efficiency. The device has a compact structure, easy operation, and is compatible with various geological conditions such as soil, sand, and soft rock. It is suitable for rural drinking water, farmland irrigation, temporary water intake on construction sites, and emergency water supply scenarios. Some models are equipped with tire chassis, which is flexible and easy to transfer, without the need for complex installation. It is a cost-effective choice for small and medium-sized water well construction in towns, mountainous areas, and wilderness areas

| Parameter | Value |

|---|---|

| Model | Shitan ST 200 |

| Max Drilling Depth | 200m |

| Drilling Diameter | 105-350mm |

| Air Pressure | 1.2-3.5 Mpa |

| Rod Length | 3m |

| Rod Diameter | 76-89mm |

| Main Shaft Pressure | 4T |

| Lifting Force | 18T |

| Power Head Stroke | 40m |

| Max Rotary Torque | 5900 Nm |

| Max Rotary Speed | 30-120 r/min |

| Secondary Winch Lifting Force | 1T |

| Jacks Stroke | 1.35m |

| Moving Speed | 2.5 km/h |

| Uphill Angle | 21° |

| Weight | 5.5T |

| Engine | Xidong 65kw(Powerful) |

| Overall Dimensions | 4400*2150*2200mm |

| Working Condition | Loose layer and bedrock |

Daily maintenance precautions

Check key components before and after homework, including drill rods, drill bits, hydraulic systems, and braking devices, and replace worn or loose parts in a timely manner.

Keep the equipment clean, remove soil and drilling debris from the drilling tools, and prevent impurities from entering the transmission and hydraulic systems.

Regularly add lubricating oil to moving parts such as gears, bearings, and chains, and select the appropriate model according to the instructions to prevent dry wear and damage.

Long term maintenance precautions

After the homework is completed, park the equipment in a dry and ventilated place, and take measures to prevent rain, moisture, and dust to prevent metal parts from rusting.

When idle for a long time, it is necessary to empty the hydraulic oil, fuel, and coolant, start the equipment regularly, and maintain the flexibility of the components.

Regularly inspect circuits, oil pipes, and seals, promptly repair damaged areas, and prevent safety hazards such as oil leakage and electric leakage.

Precautions related to operation

Strictly follow the operating procedures to avoid overloading drilling and prevent equipment damage caused by overloading.

Regularly calibrate instruments and control systems to ensure accurate parameters and guarantee drilling efficiency and safety.

|

|

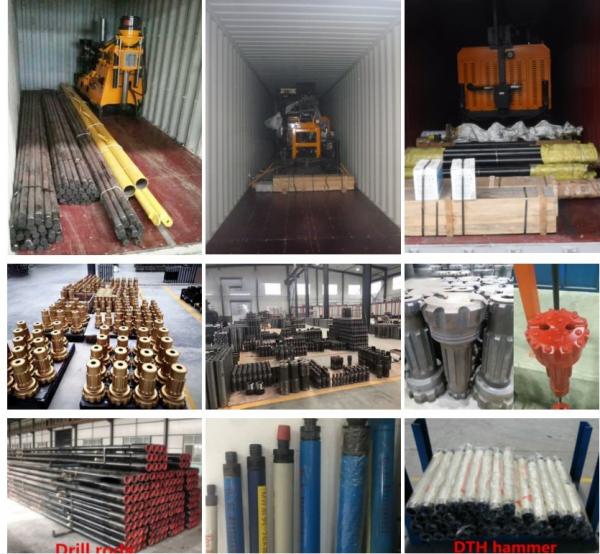

High Precision 200 Type Drilling Rig With High Power Images |